The challenge

Optimizing production and transport costs is a major challenge for any company operating on a global scale. In this case, the company in question has over 40 factories worldwide. Each plant manufactures some, but not all, of the company’s products. Each plant has different variable costs. Depending on the country of origin and destination, transport costs (before and during shipment) vary, as do customs rates.

The challenge in this situation is obvious: how can we optimally distribute product production to minimize operating costs, taking into account all these factors (production, transport, customs)?

The solution

In this case, the solution can be divided into two phases. In the first phase, a tool can be developed to calculate complete production costs by combining all available information: factory operating costs, customs cost combinations between products, origins and destinations, and (estimated) transport costs. This tool is then used as a query tool, to estimate the optimal sourcing strategy for a product in a specific destination. Depending on the company’s level of data maturity and integration, this first phase can be simple or laborious (no unified database across plants, departments, etc.). In all cases, it is crucial to define a clear information architecture and retrieve all existing data, wherever it resides.

Once this query tool has been developed, the second phase consists of adding a dynamic, proactive layer to it. This takes the form of artificial intelligence, a recommendation mechanism suggesting optimal sourcing strategies for the coming months, based on a sales forecast provided. The recommended optimal sourcing strategies can be optimized on the basis of various criteria, such as total cost, CO2 emissions (due to transport), similarity with the current situation, minimum plant occupancy, etc.

The potential gain

In many cases, the first phase of this solution is already shedding valuable light on production costs and the impact of different factors on the final cost. This is already helping to guide future operational decisions.

In the second phase, the return on investment depends on the optimization criteria chosen. If sourcing is optimized solely on the criterion of total cost, it can lead to extensive adaptations of sourcing compared to current situations, resulting in reductions in operational costs.

Further information on this project

Customer activity

- Food industry

Solution brand

- Microsoft

- Power BI

- Azure

- Python

Type of work

- Resource optimization

- S&OP

Services

- Offline Data Science and Optimization

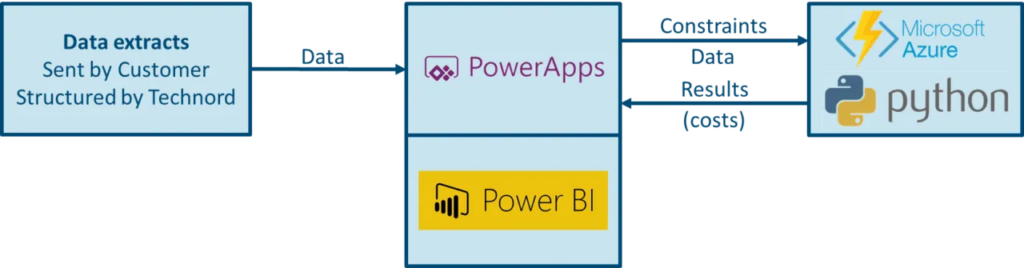

Architecture