The transition to more sustainable mobility requires innovative industrial infrastructures. This is the approach adopted by ACC (Automotive Cells Company), which launched production of its first Gigafactory in Billy-Berclau, Hauts-de-France, at the end of 2023. This plant, dedicated to the manufacture of batteries for electric vehicles, marks a key step towards European energy sovereignty.

A demanding industrial environment

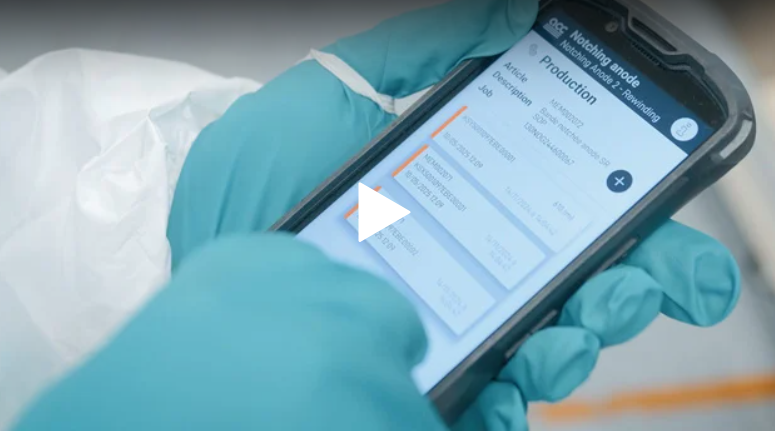

Producing batteries on a large scale means mastering complex processes, combining cutting-edge chemistry and advanced industrial technologies. To meet these requirements, ACC was faced with a major challenge: to design a high-performance MES (Manufacturing Execution System) capable of controlling production in real time, ensuring complete traceability and optimizing quality.

A strategic technological partnership

To bring this project to fruition, ACC relied on a solid partnership:

- Factory Software, distributor of AVEVA solutions, world leader in industrial software,

- Technord, expert integrator of automation and industrial digitalization.

Together, they have designed a digital factory that was conceived from the outset to be agile, connected and scalable.

A plant looking to the future

Thanks to this digitalization, ACC benefits from precise control of its operations, greater responsiveness to production contingencies, and the ability to guarantee quality at every stage of the process. It’s a model of the industry of the future, serving the energy transition.

ACC’s Gigafactory is not just an industrial feat, it’s also a powerful symbol of French and European innovation. By focusing on digitalization right from the design stage, ACC is leading the way towards smarter, more sustainable and more competitive production.

To view the video, click on the link below:

https://www.factorysoftware.com/fr/temoignage-client/acc-automotive-cells-company